|

|

Our project is an automation of a dump truck that moves linearly on top of a box. The system around it is designed to drop a marble in the back, which is carried by the truck and deposited at the end of the box on a person. The marble travels down a rut and is deposited on a rising conveyer belt. The belt takes it to a tower positioned over the dump truck (on the opposite end). Sensors on the track of the dump truck tell when it's below the tower, opening a trap door which deposits the marble in the back for the motion to start again. Other computational additions, which were not completed, include a mechanism for making sound as the truck reverses direction and a mechanism for moving the person (to avoid the marble).

Our design process had humble beginnings. After playing with the MIT crickets for a while, one of our group members pointed out the sound they produced could be quite annoying. This lead to the idea of creating a moving dump truck that beeped as it reversed direction. In the initial brainstorms it was decided that a continually reversing (and continually beeping) truck wasn't what we wanted. Instead we opted for creating linear motion governed by the turning of a crank. This would be our first and largest design problem, how to map constant rotational motion onto reversing linear motion. Not to let brainstorming be stopped by major design hurdles, we also wanted to include a mechanism for carrying something in the dump truck. Since the idea is to have some kind of repeated motion, or at least something that doesn't require hand adjustment to use again, we wanted to make a system that would reload what the dump truck would carry. A marble seemed an excellent choice, as it would be easy to filter through a system of ramps. At this point, we had a more complete picture of what our project would be, yet it was entirely too benign. Thus we decided to have the dump truck drop the marble on a Lego man, and optionally have the Lego man try to move to avoid it. A little violence never hurt any project.

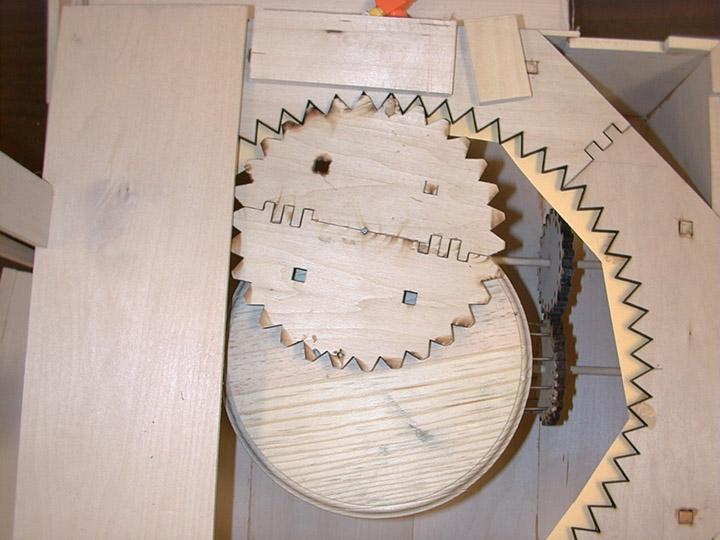

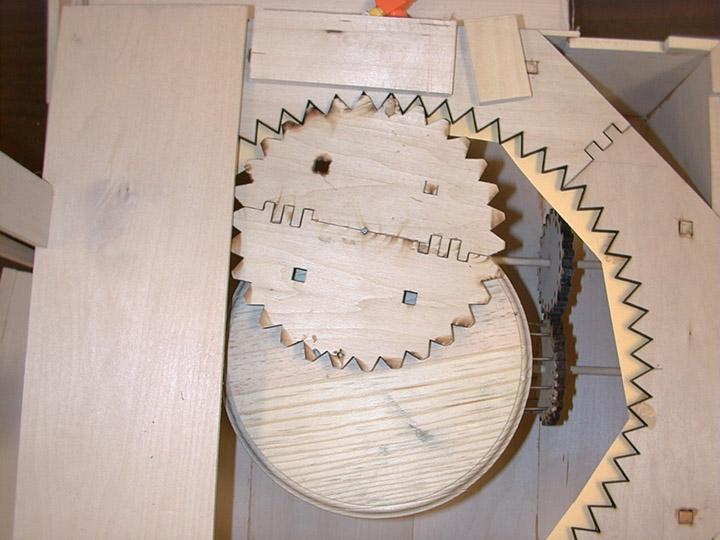

With the basic ideas laid down, we began meshing some of the implementation. The first part would be finding a way to produce reversing linear motion. One idea centered on a horizontal conveyor belt, which would pull the truck back and forth from below a platform (figure 1). At the time, it seemed promising, as it provided the required motion, wouldn't require any sophisticated construction, and was conceptually simple. However, during a class discussion, the voices of experience pointed out several potential flaws involving the tension of the belt, the pulling power it would have, and the general robustness of the system. An interesting alternative was suggested. Leonardo Da Vinci once described linear motion by using two circles. One, with diameter 1/2d, rotates inside the other, with diameter d. A point on the edge of the smaller circle will move in a line through the center of the larger circle (figure 2). The sheer elegance of the mechanism swayed us to drop the conveyor belt idea. We decided we would construct something similar, with a rod protruding from the smaller disk to the truck. The smaller disk would rest on a much larger disk situated below. Using nails, we would construct a pinwheel gear on the lower disk that would enable us to have the crank on the side of the base, as opposed to being below (figure 3). A stop on one side of the base would be used to dump the contents of the truck (figure 4). The other mechanisms seemed simple in comparison, even though this part was relatively straightforward.

As for the marble, after being dumped on the Lego-man, it would roll through a slanted passage around the side of the base to a vertical conveyor belt. The conveyor would carry it up to another ramp that would allow the marble to roll directly over truck on the other side of the base. We didn't think it was feasible to attempt to time the system precisely enough such that the marble would drop exactly as the truck passed under. Thus we needed some kind of mechanism to only allow the ball to drop only when the truck was underneath the arm. The resulting idea was to use a cricket with a touch sensor and a motor to open a trapdoor.

At this point, we were beginning to think we had a significant amount of work on our hands. Other add-ons such as the beeping and the moving Lego-man were to be added only after most of the rest of the project was complete. We discussed ideas for each but never decided on concrete plans. A few things we tossed around were to use rotational sensors to detect when the truck was going backwards and a sliding stand attached to cricket-driven-motors for the Lego- man. In the end, these ideas fell by the wayside.

Deciding on specifics of scale was heavily governed by the target size of the truck, which was to be something close to a small toy car, and the constraints of the tools available. We decided the best way to accurately create two circular gears of the correct size was to use a laser cutter. As happenstance would have it, there was one just waiting for our use. It did have some size limitations that meant we would either be forced to create a very small scale automata or cut separate pieces and attach them together. The latter path was chosen. Exact sizes were calculated and the gears took shape on paper. However, the laser didn't like our paper. At least, not for reading. Verbal commands and even threats went ignored until finally the lab technicians intervened with explanations that the laser was blind and deaf. Apparently we would need to use something called a computer to instruct the laser on how to function. Several tools were available, but they couldn't produce the exact gears we needed. Since the widest piece of wood that we could use was 4 inches wide, the gears had to be drawn so that they would fit on the wood. To do this, the largest gear was divided into 4 equal parts (figure 5) and the smaller gear was divided into 2 equal parts (figure 6). Thus Yuh-Wen undertook the heroic task of manually plotting the gears, point by point. After several years, she emerged from her cave and we did some test cuts of a thick cardboard paper. The gears seemed to stick a little bit so we decided to shave the edges of the inner gear down. That seemed to take care of the problems and we moved to wood.

The central mechanism worked out well using wood cut from the laser. We did have to double stack it to get slightly thicker pieces. The pinwheel gear was purchased, as there was no chance of extreme accuracy and it was too large and thick to be easily produced by the laser anyway. The conveyor belt was also simply bought, which alleviated quite a bit of the construction process. It came in a kit that included everything to get it rotating on two dowels and connected to the base. We sanded parts of the outside of the belt and glued marble holders on. These were small, elevated pieces of wood to which we attached 4 prongs of wire. The wire held the ball and would pass through the holders on the top and bottom of the setup, which were also made of wire. A small problem was encountered on the top; the ball would fall between the space of the wire and the conveyor belt. A stop was needed, so extra holders without wire were added at the appropriate spaces to keep it going to the upper ramps.

Other small problems included not making the ramps from the dump spot to the lower part of the conveyor belt quite steep enough to begin. The ball would occasionally get stuck, at the L-joint, but this was fixed when we added a curving join made of paper. The prongs on the conveyor belt inflicted significant amounts of pain in the attempt to get them just right, and remained picky in operation. One of our largest problems was with the main Da Vinci mechanism. The lower disk was slightly loose and would tilt during rotation. This put significant pressure on the upper disk and on occasion it would pop out. Inconsistencies in the nails used in the pinwheel gear contributed to the problem as well. We fixed it by straightening the nails, stabilizing the lower disk and adding guides for the upper disk made of paper.

We never finished the computation aspect of the project. This was a major letdown. The mechanical aspects involved much more work than we anticipated and most of the computation was intentionally left until last. Even the simple (and necessary) addition of the cricket to control the trapdoor above the truck was never completed. From the start, the design seemed relatively simple, yet implementation details bogged us down pretty quickly. It has certainly been an eye-opening experience for most of our group in showing how difficult automata creation can be. In the future, we intend to create a much simpler mechanical side of things and focus more on computation.

Our project falls into the much larger class of automata that are just fun to watch. They seem to educate by stimulation through novelty. Anyone who is remotely interested in how things work tends to be fascinated by automata. We can't prove our project will educate anyone about anything, but we'd like to think that just by watching the motion, watching the parts interact, someone would come away with a better understanding of some mechanical concepts. Perhaps not even a cognitive improvement specifically in higher level mechanics, but they would have a deeper change in the realm that intuition lurks.

Our automaton is comprised of many very simple constructs. The front of the base is open and if the top was composed of some transparent material as intended, all of its components are visible. While individually, most of the mechanics are simple, connected together they seem to make an interesting system. Certainly Da Vinci's main motion is intriguing and far from intuitive. Looking at just that, one might not immediately guess the resulting motion if it was stationary. The pinwheel gear is an example of connecting two gears at right angles, and a normal gear connection is present as well. The conveyor belt is very simple mechanically but the fact that the marble is returned from start to finish adds some interest.

We tried to be humorous in the design and construction, but many of the extra components were left off due to time constraints. For example, the inclusion of the Lego-man as a target for dumping the ball was one humor device. Of course, no one said it was quality humor. Some of the more annoying aspects, such as the beep on reverse-direction, were also left off, but perhaps that's a good thing. The component where the Lego-man would try to avoid the falling ball would have been an excellent addition, but even more sophisticated to pull off.

In truth, I'm not sure how much education can be gained by simply watching an automata. However, if someone becomes interested in the subject enough to create their own, then you have achieved real value. We had a more than a taste of that in our own projects. It was fun to design, slightly less fun to implement, but throughout it was educational. Members of our group who were not as exposed to mechanical construction got a taste of the imprecision of the real world, but also of the pride of having created something one can hold in their hands.